GALLERY

New Machines

This shows the versatility of the modular frame with the top half of an upper machine removed to aid the assembly of the conveyor.

Shown are the anti-kickback fingers in the foreground and the segmented chip break shoes farther inside the machine.

The conveyor belt is automatically kept tracking in the center of the conveyor with a pneumatic tracking mechanism.

In this photo we see the Newman technicians making the final adjustments prior to the factory run off and final paint.

The Newman Widebelt Sanders and Planer/Sanders all have an extremely heavy modular frame that allows for heads to be added or in many cases changed in configuration after they have been in operation and the application changes. These frames are fabricated from 1” thick steel plate.

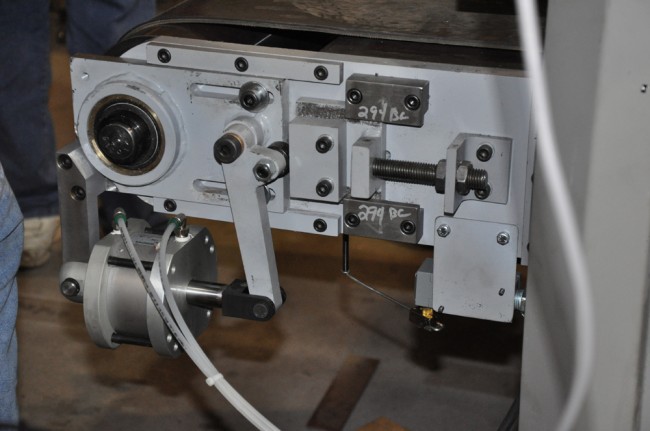

In this photo we show the cam rollers that allow the conveyor to be rolled out of the machine for maintenance.

The Newman Helical Planer head in these machines is 9 ¼” diameter. This increases the stiffness of the planer head and allows the wide machines to run faster feed speeds and take more stock than all of our competitors, without experiencing the whip of the smaller diameter heads.

Most machine systems use chains and cross shafts to drive the jacks in unison. The Newman system is all shaft drive negating the loose movement and downtime associated with broken and loose chains. All jack shafts have at least one splined connector to make adjustments from jack to jack easy and positive. Each individual conveyor bed jack is rated at 5 tons each and is of a precision anti-backlash type.

The Newman sanding heads incorporate a center pivoted upper idler for tracking control of the long 103” sanding belts. These 103” belts run cooler and sand longer while producing a better finish than the shorter 75” belts found on other machines. The dust hoods on these heads are two point pick up hoods that keep the inside of the sanding sections cleaner and help keep the belts tracking smoothly, improving the finish.

Machine Rebuilds

Expert Cemco Rebuilding & Refurbishing

Our years of experience building Cemco Machines in the factory make us uniquely qualified to bring Cemco machines back as close to new condition as possible. We can assess your machine’s condition and give you an estimated cost for this option.